Quality Policy

Innovation & Efficiency

Innovation-driven development

Pursue higher production efficiency

Do Right First Time

Meticulous process

Achieve at the first time

Risk Management

Take actions in advance to achieve risk control

Continuous Improvement

Keep challenging, reviewing and improving

Customer Satisfaction

Actively respond and rectify as per request

Quality Inspection Process

01

Pre-supplier qualification & regular supplier re-evaluation

02

Incoming Quality Control (IQC)

03

Online Testing (IPQC)

Inspecting first. middle and last part of a reel of cable

04

Finished goods Quality Control (FQC)

05

Inspection of key process from cores to finished goods

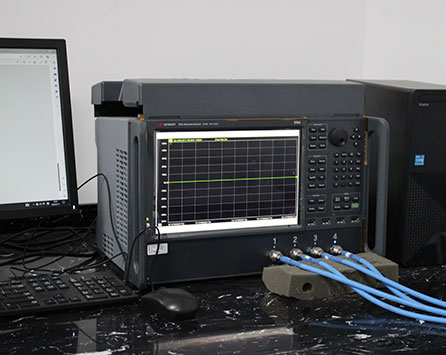

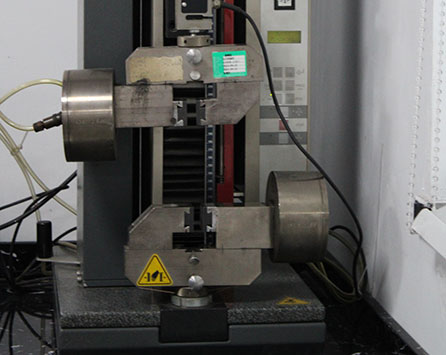

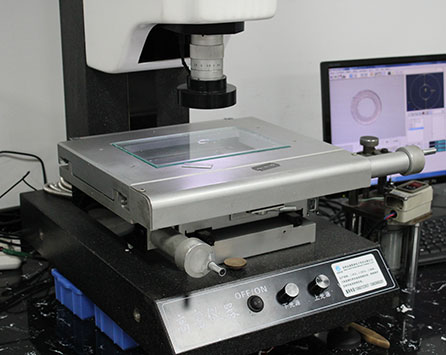

Test Equipment

Our company has 60 sets of various testing equipment, which can greatly meet the testing requirements of various cables, effectively ensuring the electrical transmission performance, physical and mechanical performance, combustion performance, etc. of cables, providing strong technical support for research and development, design, and production manufacturing.

COMMUNICATION CABLE

ELECTRIC HEAT SYSTEM